Exploring Hancock, New York on an Ego Mini-Bike: A Serene Adventure

Recently, I had the pleasure of spending some downtime in Hancock, New York, a charming town nestled in the Catskill Mountains. While my main reason for being there was for a dual sport event, I took the opportunity to explore the area on my Ego Mini-Bike. Here’s a look at my delightful experience riding through Hancock and discovering its scenic beauty.

Why Hancock?

My visit to Hancock wasn’t originally planned around sightseeing; I was there for a dual sport event. However, with some free time on my hands, I decided to use my Ego Mini Bike to explore the town. Hancock’s serene environment and picturesque landscapes made it an ideal spot for a leisurely ride.

The Ego Mini Bike: Perfect for Quiet Exploration

The Ego Mini Bike is an electric marvel, boasting a 20-mile range and speeds up to 28 mph. What sets it apart is its near-silent operation, which means you can explore without disturbing the tranquil surroundings of Hancock. Its smooth ride and nimble handling made it a perfect companion for navigating the back roads and enjoying the mountain views.

Wandering Through Hancock

Without a specific route in mind, I spent my time wandering around Hancock, taking in the sights of the Delaware River and the surrounding Catskill Mountains. The area was in full bloom, showcasing the river’s stunning beauty and the vibrant colors of spring. I especially enjoyed cruising through the quaint town, where I stopped for a refreshing ice cream at The Cow Lick and found a cozy spot along the river to read a book.

Handling the Elements

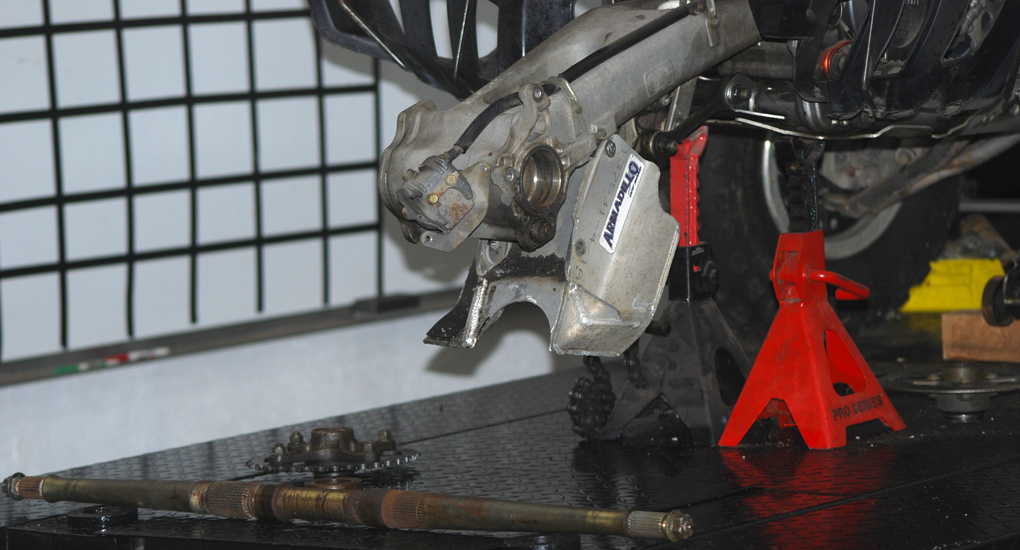

The weather over the weekend had been quite rainy, which led to some muddy conditions. Fortunately, the Ego Mini Bike’s knobby tires and powerful motor made it easy to navigate through the muck. Despite the challenging terrain, the bike handled it smoothly, adding a bit of adventure to my ride.

Local Encounters

One of the highlights of my trip was meeting a local farmer while cruising through town. He kindly gave me a tour of his property along the river and shared insights about fishing in the Delaware River. According to him, the best catches this time of year are Bass and trout, which would be a fantastic experience for any fishing enthusiast.

Reflections on Hancock

After spending some time riding around Hancock, I developed a deep appreciation for the town. Its peaceful atmosphere, friendly locals, and great food make it a wonderful place to visit. The views of the mountains and the river were particularly memorable, providing a perfect backdrop for a relaxing ride.

Tips for Future Explorers

For those planning to explore Hancock on a similar adventure, I recommend taking the cart paths and dirt roads. These routes offer a more intimate view of the town and its surroundings, making for a more immersive experience.