Winterizing Your Equipment

A Comprehensive Guide to Ensure Peak Performance

Introduction: As winter approaches, it’s crucial to prepare your equipment for the colder months ahead. One key aspect of winterizing is protecting your machinery from the potential harmful effects of ethanol-containing fuels, such as pump gas. In this guide, we’ll walk you through the steps to safeguard your equipment, ensuring it’s ready to perform at its best when spring arrives.

Step 1: Remove Ethanol-Containing Fuel

Ethanol, commonly found in pump gas, can lead to various issues when left in your equipment during winter. It absorbs water, causing corrosion and fuel system damage. To prevent this, start by completely draining your equipment’s fuel tank. Ensure that no traces of ethanol-containing fuel remain.

Step 2: Top Off with Non-Ethanol Fuel

Once the tank is empty, refill it with a high-quality, non-ethanol fuel like tru-fuel. This ethanol-free alternative provides stability during storage, reducing the risk of fuel system problems. Run your equipment for a few minutes to circulate the ethanol-free fuel throughout the entire system, replacing any remnants of the previous fuel.

Step 3: Battery Maintenance

Your equipment’s battery is another critical component that needs attention during winterization. Ideally, removing the battery and storing it in a warm environment is the best practice. However, if that’s not feasible, keeping it on a genius tender will suffice. This ensures the battery remains charged and ready for action when you need your equipment again.

Additional Tips:

- Inspect and Clean: Before storing your equipment, take the time to inspect and clean it thoroughly. Remove any debris, grease, or dirt that may have accumulated during use.

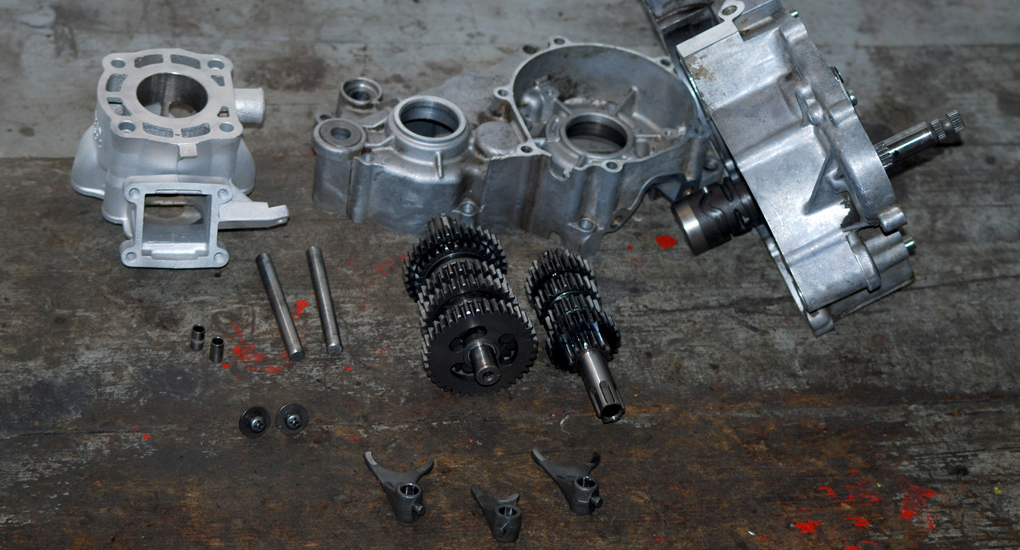

- Oil Change: Consider changing the oil in your equipment before storing it for the winter. Fresh oil will protect the engine components and ensure smooth operation come spring.

- Protective Covers: If possible, use protective covers to shield your equipment from the elements. This extra layer can prevent rust and keep your machinery in top condition.

- Check for Leaks: Before finalizing the winterization process, inspect your equipment for any signs of leaks. Addressing issues now can prevent bigger problems down the line.

Conclusion: By following these steps, you’re taking proactive measures to preserve the integrity of your equipment during the winter months. Ethanol-free fuel and proper battery maintenance are key components in ensuring that when spring arrives, your machinery is ready to tackle any task. Invest the time in winterizing now, and you’ll thank yourself later when your equipment performs flawlessly after the winter thaw.