Achieving a Premium Cut: The Art of Sharpening Lawn Mower Blades

A lush, well-manicured lawn can be the pride of any homeowner. However, achieving that perfectly trimmed grass requires more than just regular mowing; it requires attention to detail, including the often overlooked task of sharpening lawn mower blades. Contrary to popular belief, simply having a razor-sharp edge isn’t enough to ensure a clean cut. The key lies in maintaining the proper angle and pitch of the grind.

The Importance of Proper Blade Sharpening

Imagine trying to slice through a loaf of bread with a dull knife versus a sharp one. The difference in results is clear – a dull blade tears and crushes, while a sharp blade effortlessly glides through, leaving clean, precise cuts. The same principle applies to lawn mower blades.

When your mower blades are dull or improperly sharpened, they tear and shred the grass rather than cleanly cutting it. This not only creates an unsightly lawn but can also stress the grass, making it more susceptible to disease and pest infestations. Regularly sharpening your mower blades is essential to maintain a healthy and attractive lawn.

Understanding the Angle and Pitch

Many people mistakenly believe that the sharper the blade, the better the cut. However, the angle and pitch of the grind are actually more crucial than the sharpness itself. A blade that is too thin and sharp is prone to bending during use, resulting in a blunt edge that rips rather than cuts the grass.

The ideal angle and pitch of the grind will vary depending on the type of mower and blade you have. Consult your mower’s manual or seek advice from a professional to determine the optimal specifications for your equipment.

The Sharpening Process

Sharpening lawn mower blades may seem like a daunting task, but with the right tools and technique, it can be relatively straightforward. Here’s a basic guide to sharpening your mower blades:

- Safety First: Before you begin, always disconnect the spark plug to prevent accidental starts. Wear gloves and eye protection to protect yourself from sharp edges and debris.

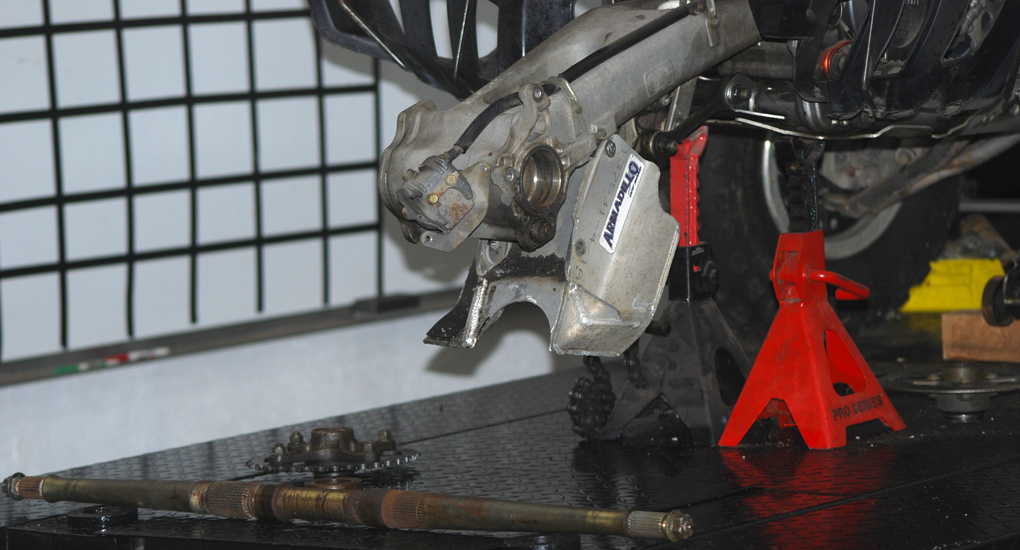

- Remove the Blade: Use a wrench to loosen and remove the bolts holding the blade in place. Take note of the orientation of the blade to ensure you reattach it correctly.

- Inspect the Blade: Take a close look at the blade for any signs of damage or wear. If the blade is severely damaged or bent, it may need to be replaced rather than sharpened.

- Sharpening: Use a grinder, file, or sharpening stone to sharpen the blade, following the manufacturer’s recommended angle and pitch. Take care to maintain a consistent angle and avoid overheating the blade, as this can weaken the metal.

- Balancing: After sharpening, it’s essential to balance the blade to prevent vibration and uneven cutting. This can be done using a specialized balancing tool or by suspending the blade on a nail or screwdriver and adjusting until it rests level.

- Reinstall the Blade: Once sharpened and balanced, reattach the blade securely, making sure to tighten the bolts firmly.

Conclusion: A Premium Cut Awaits

In conclusion, achieving a premium cut for your lawn starts with proper blade maintenance, including regular sharpening. Remember, it’s not just about sharpness – the angle and pitch of the grind are equally important factors in ensuring a clean and healthy lawn. By following the correct sharpening techniques and paying attention to detail, you can enjoy a beautifully manicured lawn that enhances the beauty of your outdoor space.